Compressor Blade - Titanium Alloy

Compressor Blade

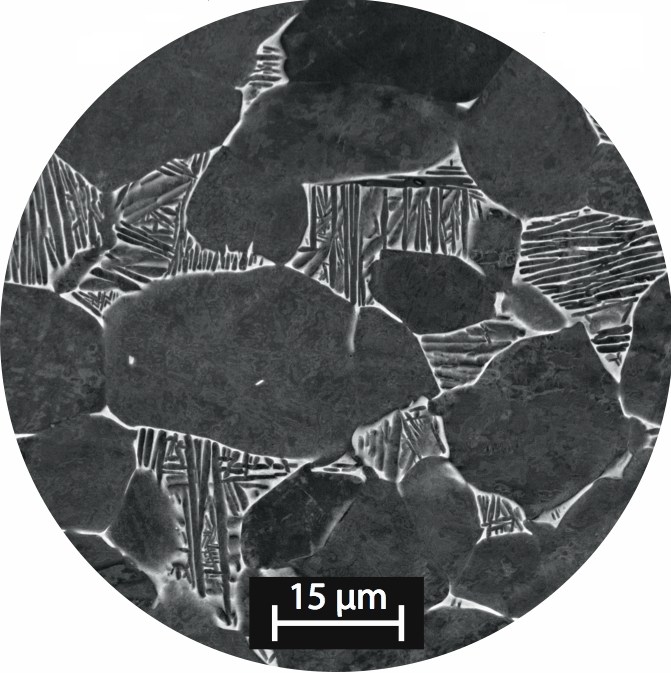

This image shows the structure of a compressor blade based on Titanium.

You may notice areas of different colours: dark and bright grey. The colour we observe in the SEM image is dependant both on the arrangement and type of atoms that are present in the structure. For example, the brighter regions for example contain more heavy elements.

The different arrangements of the atoms, and types of atoms, in the regions, will result in different properties in the different areas.

This material we can see is made up of two distinct regions: the larger dark grey crystals, and the smaller 'stripy' regions. These stripes are caused by a a series of layered plates. The dark regions make up the bulk of the image above and are made up of very light atoms. Consequently the material itself is very light, so perfect for use in aeronautical applications where we want to keep the weight to a minimum.

The bright grey 'stripped' zones contain more heavy elements and provides strength to the material. Combined, a material can be created that is both strong and light by using the advantages of each atomic arrangement. This makes it perfectly suited for use in the compressor blades in the Jet Turbine engine (find out more about the parts of the engine here). However, the material loses some of it's properties at high temperature, so is not used in the hotter parts of the engine (like the turbine blades). Instead these are made from a different type of material known as a superalloy. Compare the difference between this titanium alloy and the structure of a superalloy.